Introduction:

Filters are essential components in various industries and applications, serving to remove impurities, contaminants, or unwanted particles from liquids or gases. Two common types of filters are metal mesh filters and fiberglass mesh filters. While both serve the same purpose, they have distinct characteristics that make them suitable for different applications. This essay aims to explore the differences between metal mesh filters and fiberglass mesh filters, focusing on their construction, materials, applications, and advantages.

Construction and Materials of Metal Mesh Filters and Fiberglass Mesh Filters:

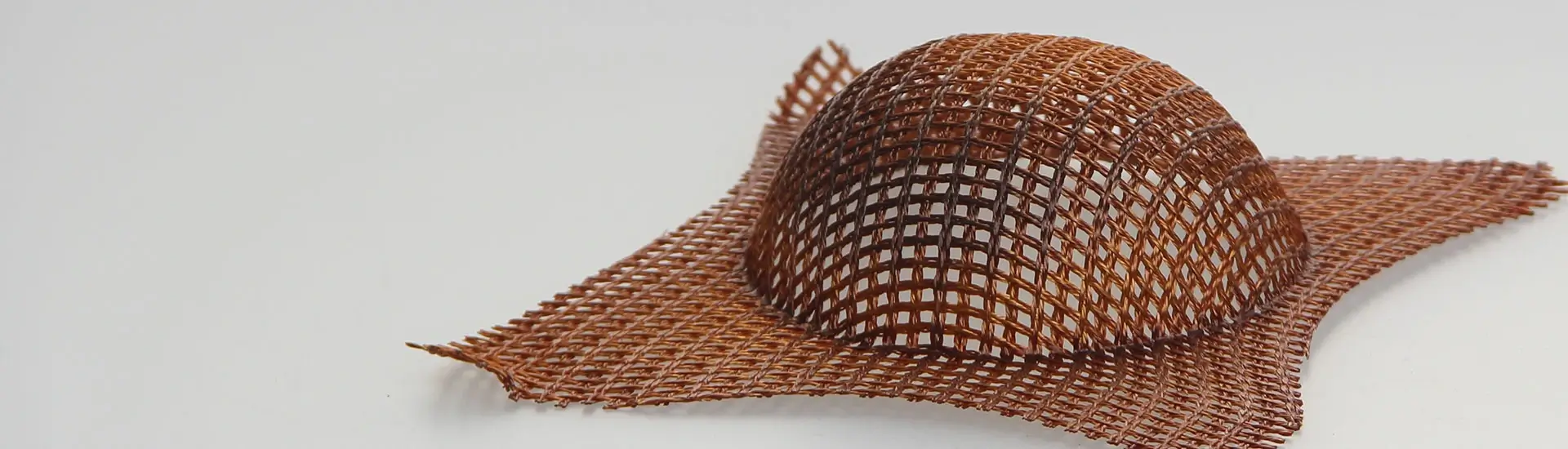

Metal mesh filters are typically made of woven or sintered metal wires, such as stainless steel, aluminum, or copper. These wires are woven or sintered together to form a mesh structure with precise openings that allow the passage of desired particles while trapping larger ones. The construction of metal filters can vary in terms of wire diameter, mesh count, and weave pattern, allowing for customization based on specific filtration requirements.

Fiberglass mesh filters, on the other hand, are made of fiberglass strands that are woven or knitted together to create a mesh structure. The fiberglass strands are typically coated with a resin to improve durability and resistance to chemicals and temperature extremes. Fiberglass mesh filters are known for their high tensile strength, flexibility, and resistance to corrosion, making them suitable for demanding filtration applications.

Applications of Metal Mesh Filters and Fiberglass Mesh Filters:

Metal mesh filters are commonly used in industries such as automotive, aerospace, oil and gas, and HVAC (heating, ventilation, and air conditioning). They are preferred for applications that require high-temperature resistance, durability, and the ability to withstand harsh environments. Metal filters are also used in applications where precise particle retention is essential, such as in the pharmaceutical and food and beverage industries.

Fiberglass mesh filters are widely used in applications where chemical resistance, flexibility, and cost-effectiveness are important factors. They are commonly used in air filtration systems, water treatment plants, and chemical processing industries. Fiberglass mesh filters are also used in residential and commercial HVAC systems due to their ability to capture fine particles and allergens.

Advantages of Metal Mesh Filters and Fiberglass Mesh Filters:

Metal mesh filters offer several advantages, including high-temperature resistance, durability, and precise particle retention. They are also easy to clean and maintain, making them suitable for applications where frequent cleaning is required. Additionally, metal filters can be customized to meet specific filtration requirements, making them versatile and adaptable to various industries and applications.

Fiberglass mesh filters are known for their chemical resistance, flexibility, and cost-effectiveness. They are lightweight and easy to handle, making them ideal for applications where weight and space constraints are important considerations. Fiberglass mesh filters also offer excellent filtration efficiency and can capture fine particles and allergens, making them suitable for air and water filtration systems.

Conclusion:

In conclusion, metal mesh filters and fiberglass mesh filters are two common types of filters used in various industries and applications. While both serve the same purpose of removing impurities and contaminants, they have distinct characteristics that make them suitable for different applications. Metal filters offer high-temperature resistance, durability, and precise particle retention, while fiberglass mesh filters offer chemical resistance, flexibility, and cost-effectiveness. Understanding the differences between these two types of filters is essential for selecting the most suitable option for a specific filtration requirement.