The foundry industry is crucial for the manufacturing of numerous products, including automobile parts, household appliances, and aerospace equipment. To ensure the quality and durability of these products, foundries need to use advanced techniques and tools, including ceramic foam filters. These filters are becoming increasingly popular due to their effectiveness in removing impurities from molten metals. This article aims to provide an overview of the ceramic foam filter market, its presence in the foundry exhibition, and current market trends.

Introduction

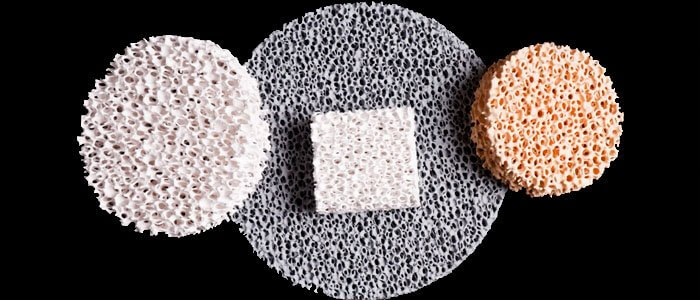

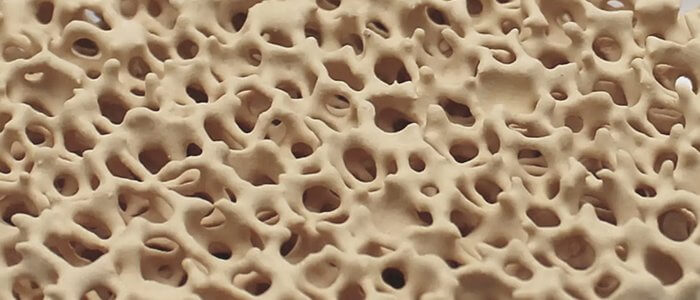

The demand for high-quality metal products has driven advancements in the foundry industry. This has resulted in the development of more efficient processes and the use of modern equipment, including ceramic foam filters. Ceramic foam filters are made by ceramicizing a plastic foam made of polyurethane and similar materials. The resulting filters are porous, with interconnected cells that trap impurities and allow molten metals to pass through.

The foundry industry has seen tremendous growth in recent years, with advancements in technology and globalization contributing to this trend. The ceramic foam filters market is no exception. According to a report by Grand View Research, the ceramic foam filters market is expected to reach $510.2 million by 2025, growing at a CAGR of 4.5% from 2020 to 2025. This growth is due to factors such as the increasing demand for metal casting from various end-use industries and the need for high-quality products.

Ceramic Foam Filters in the Foundry Exhibition

The foundry exhibition is an essential platform for stakeholders in the foundry industry to showcase their latest products and innovations. Ceramic foam filters are a prominent feature of this exhibition, highlighting their effectiveness in ensuring the high quality of final products. These filters are an integral component of the casting process, with their ability to remove impurities contributing to the physical and mechanical properties of the final product.

At the foundry exhibition, ceramic foam filters are showcased by numerous companies, including Vesuvius, SELEE Corporation, and Pyrotek. These companies highlight their products’ unique features, including their high-temperature resistance, low-density, and excellent filtration efficiency. Visitors to the exhibition can engage with these companies and learn more about how ceramic foam filters have transformed the foundry industry.

Market Analysis

The growth of the ceramic foam filter market is driven by various factors, including the increasing demand for metal casting from different industries. The automotive industry is a significant contributor to this growth, with the development of electric vehicles, resulting in a shift towards lightweight materials such as aluminum and magnesium. The use of ceramic foam filters in the casting of these materials has become a critical factor in ensuring the high quality of final products.

Furthermore, the aerospace industry’s growth has driven the demand for high-performance materials used in spacecraft, satellites, and aircraft. The lightweight and high-strength properties of ceramic foam filters make them an essential component in the casting process of these materials.

The market for ceramic foam filters is also driven by the increasing standards for product quality across industries. Quality control in the foundry industry is becoming more stringent, with manufacturers facing stricter regulations and requirements. Ceramic foam filters, with their ability to remove impurities and improve product quality, are essential in meeting these standards.

Conclusion

The foundry exhibition provides an opportunity to explore the latest developments in the foundry industry, including ceramic foam filters. These filters are an essential component of the casting process, contributing to the quality and durability of final products. The increasing demand for high-quality products from different industries, including automotive and aerospace, will continue to drive the growth of the ceramic foam filters market. This growth is expected to continue in the coming years, making ceramic foam filters a key player in the foundry industry.