Introduction

Ceramic foam filters play a pivotal role in ensuring the quality and integrity of metal castings, particularly in the ceramics and foundry industries. To understand their production, we must delve into the essential raw materials and production equipment that go into making these critical components.

Raw Materials: The Building Blocks of Ceramic Foam Filters

1. Ceramic Powders:

Role: Ceramic powders are the primary raw materials used in the production of ceramic foam filters. They provide the filter’s structure and essential characteristics.

Types: Common ceramic powders include alumina, silicon carbide, zirconia, and various other refractory materials. The choice of ceramic powder depends on the intended application and the desired properties of the filter.

2. Organic Foam Precursors:

Role: Organic foam precursors are essential for creating the porous structure in ceramic foam filters. They act as temporary templates that burn away during firing, leaving behind the porous ceramic structure.

Types: Polyurethane foam, polymeric sponge, and other organic materials can be used as precursors. These materials should be carefully selected to ensure minimal ash content and residue during firing.

3. Binder:

Role: Binders are used to mix the ceramic powders and organic foam precursors, creating a homogenous slurry that can be shaped and molded into the desired filter shape.

Types: Binders can be organic or inorganic. Organic binders, such as polyvinyl alcohol (PVA), are commonly used for their water-solubility, while inorganic binders like colloidal silica provide excellent stability during the firing process.

4. Defoamers and Surfactants:

Role: Defoamers and surfactants are used to control the consistency and stability of the slurry. They help eliminate bubbles and ensure uniform distribution of the ceramic powder within the slurry.

Types: Various chemical agents can serve as defoamers and surfactants, such as silicone-based compounds.

5. Firing Aids and Sintering Additives:

Role: Firing aids and sintering additives are incorporated into the slurry to enhance the sintering process. They help in achieving the desired porosity and mechanical properties of the ceramic foam filter.

Types: Common additives include fluxes like boron oxide and sintering aids like magnesium oxide.

Production Equipment

1. Mixing Equipment:

Role: Mixing equipment is essential for blending ceramic powders, organic foam precursors, binders, and additives into a uniform slurry.

Types: High-speed mixers, planetary mixers, and ball mills are commonly used for this purpose.

2. Molding and Shaping Equipment:

Role: Molding and shaping equipment is used to form the slurry into the desired shape and size of the ceramic foam filter.

Types: Extrusion machines, injection molding equipment, and casting molds are employed for shaping.

3. Drying and Pre-firing Equipment:

Role: After molding, the filters must be dried and pre-fired to remove the organic foam precursors and binders before the final sintering process.

Types: Drying ovens and kilns are used for this purpose.

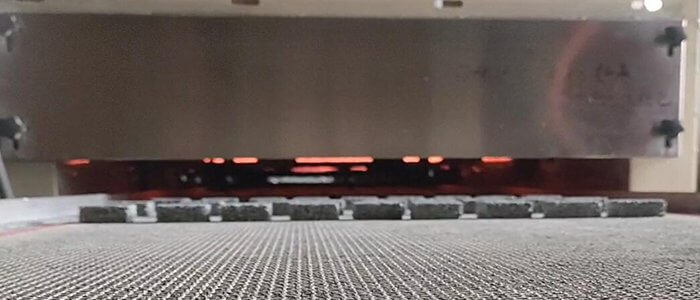

4. Sintering Furnaces:

Role: Sintering furnaces play a critical role in the production of ceramic foam filters, as they heat the shaped filters to high temperatures, causing the ceramic particles to fuse together.

Types: Electric resistance furnaces, gas-fired furnaces, and microwave sintering equipment can be used, depending on the specific requirements.

Conclusion

Ceramic foam filters are indispensable components in the ceramics and foundry industries, and their production involves carefully selected raw materials and specialized equipment.

Understanding the roles of each raw material and the functions of production equipment is crucial in creating filters with the desired properties and performance characteristics. The combination of ceramic powders, organic foam precursors, binders, and additives, along with the right production equipment, ensures the quality and effectiveness of ceramic foam filters in enhancing the quality of metal castings.