The foundry industry in Ukraine has been witnessing steady growth in recent years, driven by an increasing demand for cast metal products across various industries, such as automotive, aerospace, construction, and energy. According to a report by ResearchAndMarkets, the Ukrainian foundry market is expected to grow at a CAGR of 3.2% during the period 2020-2025, driven by the growth of end-use industries and investments in modernizing the foundry infrastructure.

The foundry industry in Ukraine is dominated by small and medium-sized enterprises (SMEs), with a few large companies operating in the market. These SMEs primarily focus on producing cast iron and steel products for domestic and export markets, with a limited focus on high-value-added products, such as alloy and precision castings.

In order to compete in the global market and meet the demands of customers for high-quality cast metal products, Ukrainian foundries are investing in modernizing their production processes, adopting advanced technologies, and implementing quality management systems. One of the key technologies that is gaining popularity among Ukrainian foundries is the use of zirconia ceramic foam filters.

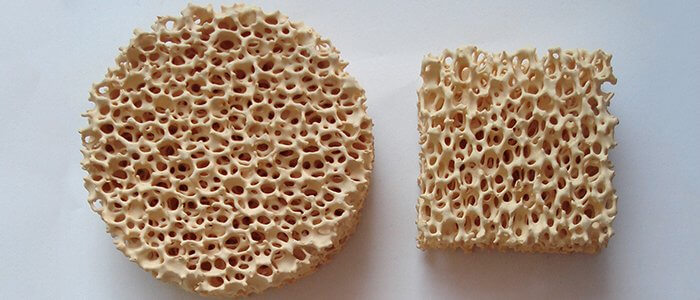

Zirconia ceramic foam filters are porous ceramic filters that are used to remove impurities from molten metal during the casting process. They are made of high-purity zirconia, which has excellent thermal and chemical stability, and can withstand high temperatures. These filters can remove impurities such as slag, oxides, and non-metallic inclusions from the molten metal, resulting in higher-quality castings.

The use of zirconia ceramic foam filters in Ukraine began in the early 2000s and has been growing steadily. According to market sources, the proportion of zirconia ceramic foam filters in the Ukrainian market has reached around 30%, which is still lower compared to other markets such as Europe, North America, and China, where the usage of these filters is much higher.

However, the increasing adoption of zirconia ceramic foam filters in Ukrainian foundries is expected to drive the growth of the market in the coming years. Factors such as the increasing focus on quality and efficiency, the rising demand for high-value-added products, and the growing awareness of the benefits of using zirconia ceramic foam filters are expected to boost the demand for these filters in the Ukrainian market.

In conclusion, the foundry industry in Ukraine is poised for growth, and the increasing demand for high-quality cast metal products is driving the adoption of advanced technologies such as zirconia ceramic foam filters. By leveraging these technologies and investing in modernizing their production processes, Ukrainian foundries can not only compete in the global market but also achieve sustainable growth.