Magnesia ceramic foam filter is a kind of ceramic material, which is widely used in industrial filtration due to its unique properties. In this article, we introduce the composition and characteristics of the Magnesia ceramic foam filter, the scope of application, typical application scenes, and foreign market analysis. We hope that this article can provide a better understanding of Magnesia ceramic foam filters for people in related industries.

Keywords: Magnesia ceramic foam filter, composition, characteristics, application scope, application scene, foreign market analysis

Introduction

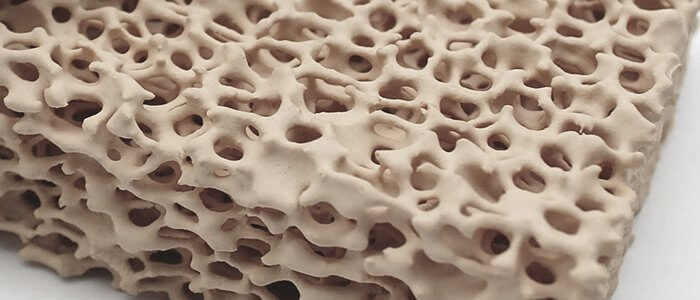

Magnesia ceramic foam filter, also known as magnesium oxide foam ceramic filter, is a kind of ceramic material made of magnesium oxide and a small number of ceramic additives through a foaming process. This filter plate has the characteristics of high-temperature resistance, corrosion resistance, high strength, and uniform pore size distribution. Therefore, it is widely used in metallurgical, chemical, environmental protection, and other industries for the filtration of high-temperature molten metals, corrosive liquids, and gases.

Composition and Characteristics of Magnesia ceramic foam filter

Composition

Magnesia ceramic foam filter is mainly composed of MgO and ceramic additives. The ceramic additives are used to adjust the properties of the filter plate, such as pore size, strength, and corrosion resistance.

Characteristics

- High-temperature resistance: the filter plate can withstand high temperatures up to 1200℃, which makes it suitable for the filtration of high-temperature molten metals.

- Corrosion resistance: the filter plate has excellent corrosion resistance to acidic and alkaline solutions, making it suitable for the filtration of corrosive liquids.

- High strength: the filter plate has high strength, which enables it to withstand high pressure during the filtration process.

- Uniform pore size distribution: the filter plate has a uniform pore size distribution, which ensures filtration accuracy and efficiency.

Scope of Use of Magnesia ceramic foam filter

Magnesia ceramic foam filter is widely used in various industries, including:

- Metallurgical industry: it is used for the purification of high-temperature molten metals, such as steel, aluminum, copper, and iron.

- Chemical industry: it is used for the filtration of corrosive liquids, such as acids, alkalis, and organic solvents.

- Environmental protection industry: it is used for the filtration of industrial wastewater and flue gas, and the removal of heavy metal ions and organic pollutants.

- Other industries: it is used for the filtration of gases, such as hydrogen, nitrogen, and oxygen, and the purification of air.

Typical Application Scenes of Magnesia ceramic foam filter

- Steel casting industry: Magnesia ceramic foam filter is widely used in the steel casting industry for the filtration of molten steel. During the casting process, impurities in the molten steel can be filtered out by the filter plate, improving the quality of the final product.

- Chemical industry: Magnesia ceramic foam filter is used in the chemical industry to filtrate corrosive liquids. For example, it can be used in the production of caustic soda and chlorine, which require the filtration of brine.

- Environmental protection industry: Magnesia ceramic foam filter is used in the environmental protection industry to filtrate industrial wastewater and flue gas. For example, it can be used in the treatment of heavy metal ions and organic pollutants in electroplating wastewater.

Foreign Market Analysis of Magnesia ceramic foam filter

Magnesia ceramic foam filter is a relatively new material in the international market, and only a few countries have developed this filter plate. Among them, Japan is the most mature Magnesia ceramic foam filter market.

In recent years, China has also made great progress in the development of Magnesia ceramic foam filters. Compared with Japanese companies, Chinese companies have the advantages of lower costs and more flexible customization. At present, domestic companies such as Jiangsu Jiuyang, Yixing Huaheng, Shandong Rongtai, and SEFU CERAMIC have launched their own Magnesia ceramic foam filter products. These products have been applied in the steel casting industry, chemical industry, and environmental protection industry.

Conclusion

Magnesia ceramic foam filter is a ceramic material with unique properties, such as high-temperature resistance, corrosion resistance, high strength, and uniform pore size distribution. It is widely used in various industries, including metallurgical, chemical, and environmental protection industries. The typical application scenes include the steel casting industry, chemical industry, and environmental protection industry.